Tooling Integration

Connecting various tools and equipment with automation systems.

By seamlessly connecting various tools, dies, and equipment with factory automation systems, tooling integration transforms the way manufacturing operations are conducted.

Whether integrating into new or existing factory automation systems, our servo and hydraulic press solutions help manufacturers streamline production, improve quality, and maximize throughput.

Integration of Servo Presses

Improve process efficiency and minimize the risk of defective parts

Integration of Hydraulic Presses

Exert consistent pressure throughout repetitive tasks ensures optimal end-product quality

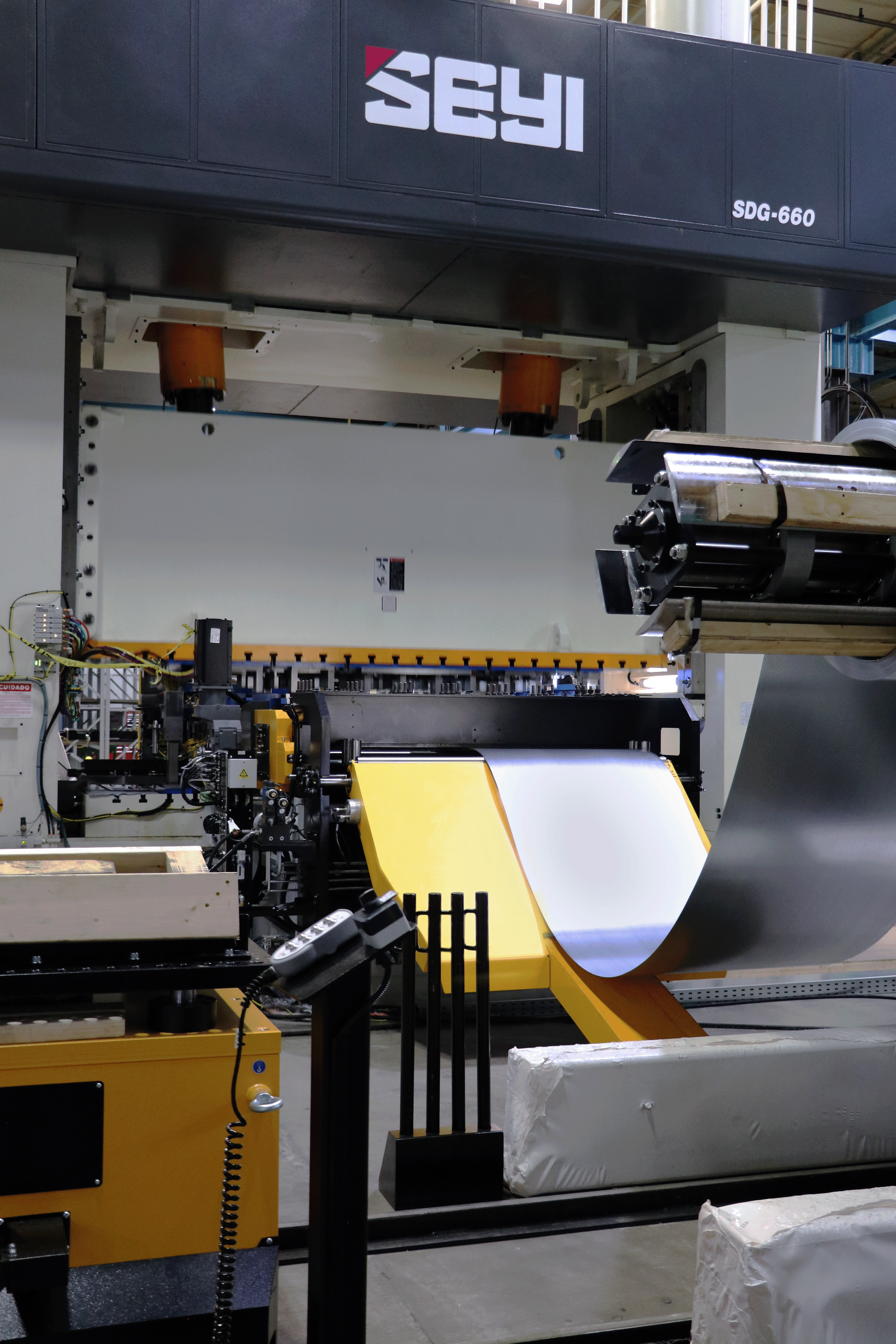

Servo Feed Systems

Automating tasks requiring intricate material handling, such as cutting, punching, or stamping operations

Integrating Servo Presses

Servo presses utilize advanced control systems and closed-loop technology to deliver unmatched precision. Key benefits include:

Precise force control, position accuracy, and speed modulation through closed-loop control systems

Customizable profiles for complex operations such as assembly, riveting, and forming

Consistent, accurate force application to improve product quality and reduce waste

Flexible programming for different materials, shapes, and sizes to reduce changeover time

Real-time force monitoring and adjustment to prevent defective parts

Integration into automation tooling systems for improved productivity tooling and streamlined production

Integrating Hydraulic Presses

Hydraulic presses are widely renowned for their immense force capabilities and versatility in tool and die manufacturing. Key advantages include:

High hydraulic pressure output for superior strength and performance

Ideal for heavy-duty applications such as metal forming, deep drawing, and shear cutting

Consistent pressure delivery to ensure repeatable, high-quality results

Excellent power-to-die proximity efficiency for energy savings and sustainability

Cost reduction benefits aligned with eco-friendly manufacturing practices

Critical support for those seeking dependable tool and die makers for heavy-duty automation

Integrating Servo Feed Systems

Servo feed systems integrate control systems and servo motors for precise, consistent material handling. Key benefits include:

Accurate speed and position control for consistent material feeding

Automation of complex handling tasks such as cutting, punching, or stamping

Seamless integration with robotics, CNC machines, and other automation equipment

Reduced downtown through synchronized operation across the production line

Boosts in productivity tooling by enhancing coordination and efficiency

Improved product quality through precise feed control and error reduction

Revolutionize your operations.

Embrace innovation and reshape the future of manufacturing.

With DT Engineering’s tooling integration expertise, your industrial operations can automate complex tasks, maintain consistent output, and gain cost reduction benefits.